Automotive Engine Rebuilding Cost Guide: What to Expect and How to Budget

When your vehicle’s engine starts showing signs of serious wear or worse, fails completely rebuilding it may be a cost-effective way to bring your car back to life. But engine rebuilding isn’t a one-size-fits-all service. Costs can vary dramatically depending on the make, model, engine type, and extent of damage. This automotive engine rebuilding cost guide is designed to help drivers understand what influences pricing, what’s typically included, and how to budget for the job. Whether you’re planning a DIY rebuild or working with a professional shop, having a clear view of the process can help you make smarter, more confident decisions.

What Factors Influence the Cost of an Engine Rebuild?

Engine rebuilding costs are shaped by several key variables. The type of vehicle plays a big role a four-cylinder engine in a compact car is far less expensive to rebuild than a V8 in a performance vehicle. Labor rates also vary by location and shop, with high-performance or specialty rebuilds costing more due to the precision required. The extent of engine damage matters as well. If only minor components like gaskets or bearings need replacing, the rebuild will be more affordable than one requiring new pistons, crankshaft work, or cylinder head machining. OEM vs. aftermarket parts, labor hours, and whether the engine is removed and reinstalled all factor into the final price.

What’s Typically Included in a Standard Rebuild?

A standard engine rebuild involves disassembling the engine, cleaning all components, replacing worn-out parts, and reassembling it to factory specs. This often includes new gaskets, piston rings, bearings, oil pump, timing components, and seals. Depending on wear, the rebuild might also involve resurfacing cylinder heads, honing cylinders, or replacing valves and guides. Rebuilding also gives technicians a chance to inspect for underlying issues that might not be obvious at first glance, such as cracks in the block or worn camshaft lobes. A quality rebuild restores performance and reliability, extending the life of the engine significantly.

Average Rebuild Costs: What Should You Budget?

On average, you can expect a basic engine rebuild to range from $2,500 to $4,500 for most vehicles. For performance engines, luxury brands, or trucks with large-displacement engines, that number can climb to $5,000 or more. DIY rebuilds can save on labor but require tools, space, mechanical knowledge, and time plus, there’s a risk of making costly mistakes. If you’re working with a professional shop, make sure you request an itemized estimate and understand what’s covered. A cheaper quote isn’t always the best option quality components and experienced labor matter more than saving a few hundred dollars upfront.

Signs You Might Need a Rebuild Instead of a Replacement

Rebuilding is often a smarter choice when your engine has significant wear but the vehicle overall is still in good shape. Signs that may indicate the need for a rebuild include low compression, knocking sounds, excessive oil consumption, or visible smoke from the exhaust. If your engine still has a strong foundation meaning the block and head are reusable a rebuild makes sense over a full replacement or buying a used engine of uncertain condition. Rebuilding also allows you to retain your original engine, which can be important for classic cars or vehicles with matching VIN numbers.

Tips for Getting the Most From Your Rebuild Investment

A properly rebuilt engine can last just as long if not longer than the original factory unit. To maximize your investment, follow break-in procedures carefully and stay on top of regular maintenance. Ask your builder about warranties and what’s included in their coverage. Document all work performed for future resale value. If you’re already investing in a rebuild, consider replacing surrounding components like the water pump, timing belt, and hoses while the engine is out. Doing so reduces future labor costs and helps avoid new failures that could affect your rebuilt engine’s performance.

FAQs About Automotive Engine Rebuilding Costs

Is rebuilding an engine cheaper than replacing it?

Often, yes especially if your engine block is reusable and you’re avoiding the cost of a full replacement or remanufactured engine.

How long does an engine rebuild typically take?

Professional rebuilds usually take 1 to 3 weeks, depending on parts availability, shop schedule, and complexity.

Does a rebuilt engine increase resale value?

It can. Buyers often appreciate a documented, professionally rebuilt engine especially in high-mileage or classic vehicles.

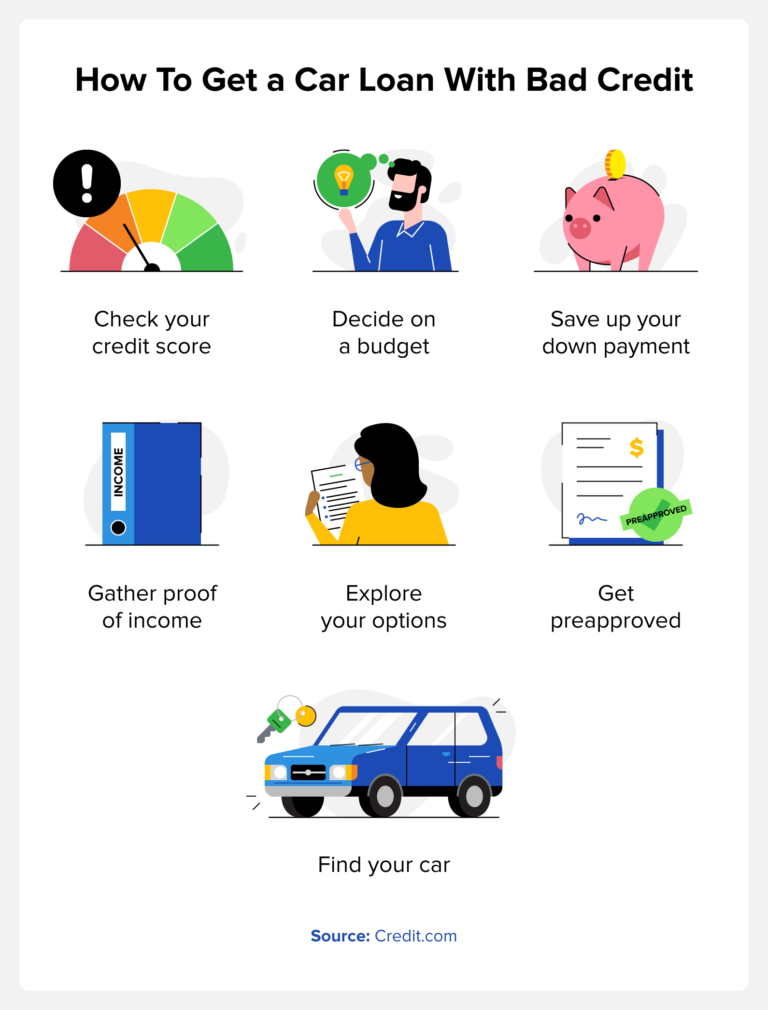

Can I finance an engine rebuild?

Some repair shops offer financing options, and third-party lenders may also help cover large repair costs.

Are rebuilt engines reliable?

When done by experienced technicians using quality parts, rebuilt engines are highly reliable and often match OEM performance.